Which of the Following Actions Would Help Prevent Chemical Hazards

Hazard Prevention and Control. 3 Be careful when using chemicals while food is being prepared.

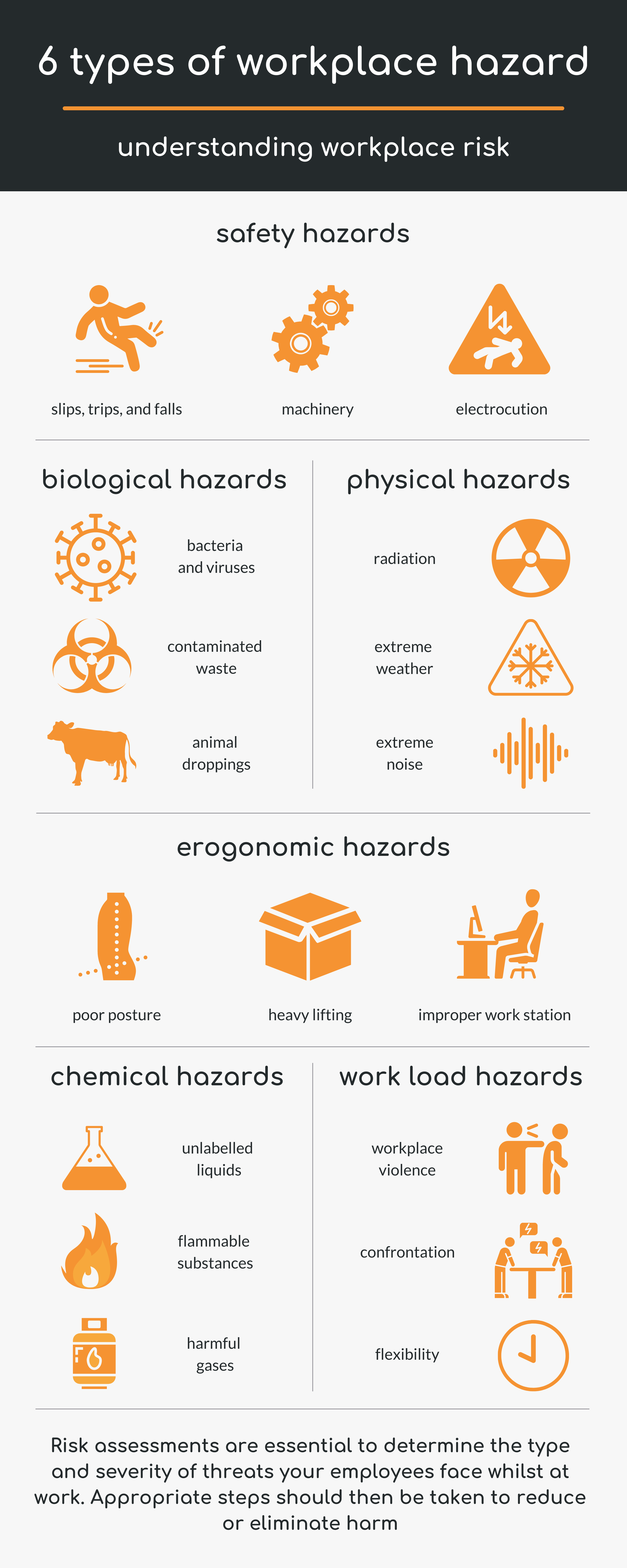

Workplace Hazards Types Of Hazard Staysafe App

This includes Elimination- Options which get rid of the hazard altogether.

. Help avoid injuries illnesses and incidents. Workers should be aware of the following chemical hazards in the workplace. Gardening can involve the use of herbicides pesticides and fertilizers.

The action of storing chemicals in a separate area away from food will help prevent chemical hazards Option a. 4 Label chemical containers when transferring a chemical to a new container. 2 Follow mfgr directions when using chemicals.

Chemical Hazards The methods in which chemicals enter the body are called routes of entry Understanding these various routes of entry is necessary to prevent exposure to hazardous chemicals. The way that this methodology can be used to manage hazardous chemicals in the workplace is that you must first identify and assess their potential risks. Chemicals such as cleaning agents and sanitizers help keep your establishment clean and safe.

Use General SOPs Each chemical has a unique set of hazards and. These four phases are. Regular inspections of chemical containers can go a long way toward preventing a hazardous spill.

Make sure the diameter of the tube or rod is compatible with the diameter of the hose or stopper. 5-minutes for non-irritants or mild irritants. Ensuring the exterior parts of the containers are free of any spills and stains.

Soil or soil from a contaminant-free area to ensure your safety. Companies should pay particular attention to. The best way to protect workers is to remove or eliminate the hazard from the workplace using the following hazard control methods.

Hazard correction information can be noted on an inspection report next to the hazard description. It provides useful information on the chemical hazards advice on safe handling use and storage and the emergency measures to be followed in case of an accident. The idea behind this hierarchy is that the control methods at the top of graphic are potentially more effective.

And help employers provide workers with safe and healthful working conditions. If not already fire polished fire. Substitute dangerous chemicals equipment or work methods with safer and less hazardous ones to eliminate the hazard altogether.

Replace the open-topped manual. Which of the following actions can help prevent exposure to bloodborne pathogens. The processes described in this section will help employers prevent and control.

The International Chemical Safety Cards offer essential health and safety information on chemicals to promote their safe use. Effective controls protect workers from workplace hazards. A vaccine is only available for which of the following major bloodborne pathogens viruses.

Once the hazards involved in the handling and use of chemicals are identified the next stage is to put control measures in place. This service is ofered for free from many Cooperative Extension Service oices. Falls from tripping over who-knows-what uneven floor surfaces wet floors loose cables etc are easily the most common cause of injuries at work.

Safety data sheet SDS A safety data sheet SDS is a document that must be provided to you with all hazardous chemicals. Slips trips and falls. Controlling exposures to occupational hazards is the fundamental method of protecting workers.

There are three main Routes of Entry Absorption Inhalation Ingestion. 1 Store chemicals away from food utensilsand equip. Most Effective Hazard Controls.

In all cases the employer has a duty of due diligence and is responsible for taking all reasonable precautions under the particular circumstances to prevent injuries or accidents in the workplace. Assessing screw caps and closures for any signs of deformity. The goal of the Chemical and Biological Hazard Prevention CBHP field is to help prevent occupational diseases and adverse health effects and to improve and maintain the health and well-being of workers exposed to chemical substances and biological agents.

Chemical hazards or at least reduce exposure to a low level. Preventive Maintenance Systems Good preventive maintenance plays a major role in ensuring that hazard controls. Engineering Controls- Fume Hoods local exhaust.

This training will help your employees understand how dangerous chemical hazards are and how to prevent them. The preferred approaches are innovation generating new knowledge conducting critical. However they can harm your employees and customers if they are not used or stored properly.

Minimize or eliminate safety and health risks. Some hazards and their controls will be specifically outlined in legislation. Chemicals can be safer to others but to some sensitive workers even the most common solutions can cause illness skin irritation or breathing problems.

It is well known that exposure to chemical hazards may lead to negative health effects or even cause death. Below are some ways to help protect your health if you use these chemicals. In situations where there is not a clear way to control a hazard or if legislation.

Employers have to fork over big bucks to cover the cost of all of these mishaps and sadly most of them could be prevented if safety regulations were followed properly. The following practices will help prevent accidents. If chemical contamination occurs your employees.

The information provided in these cards includes identity of the chemical physical and. 30 minutes for most corrosives. 60 minutes for strong alkalis eg sodium potassium or calcium hydroxide It is very important that water flushing start immediately following skin.

They are intended to be used by workers and employers as a clear communication tool. 5 Only use lubricants that are made for food equipment. Which of the following is an example of a.

Have your soil tested before you fertilize. NIOSH Pocket Guide to Chemical Hazards. This must be done before any controls are implemented to mitigate the risks associated with hazardous chemicals.

Chemical hazards can be defined as non-organic substances which are dangerous for human life. The following tips can help minimize chemical exposure in laboratories round out a chemical hygiene plan and promote worker safety. Substitution- Replacing a hazardous chemical with a less hazardous one wherever possible.

Traditionally a hierarchy of controls has been used as a means of determining how to implement feasible and effective control solutions. In addition to the chemical hazards found in laboratories there are also numerous physical hazards encountered by laboratory staff on a day-to-day basis. Employee reports of hazards and reports of accident investigation should provide space for notations about hazard correction.

15-20 minutes for moderate to severe irritants and chemicals that cause acute toxicity if absorbed through the skin. Identify - Assess - Control - Sustain. Liquids like cleaning products paints acids solvents especially if chemicals are in an unlabeled container.

Personal Protective Equipment Ppe Safety A Guide Safetyculture

Types Of Hazards National Association Of Safety Professionals

Rules For Safe Handling Of Hazardous Materials Chemical Safety Safety Guide Safety Posters

No comments for "Which of the Following Actions Would Help Prevent Chemical Hazards"

Post a Comment